Provides additional ports with automatic zero and span

Overview

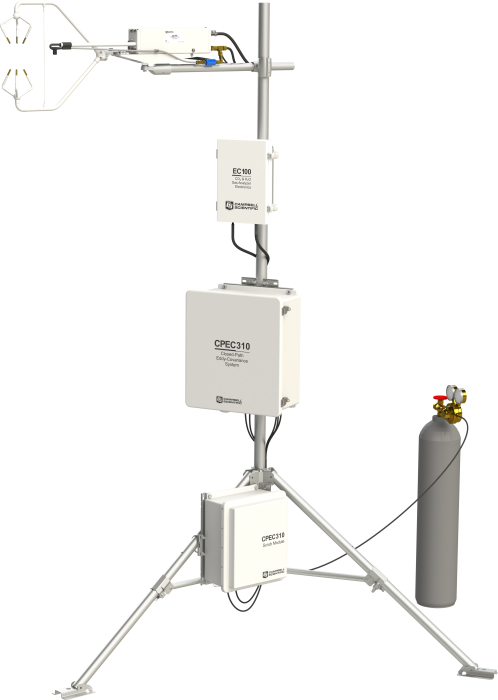

The CPEC310 with EasyFlux® is a turn-key, closed-path eddy-covariance (EC) flux system for long-term monitoring of atmospheric-biosphere exchanges of carbon dioxide, water vapor, heat, and momentum. A complete system consists of a closed-path gas analyzer (EC155 closed-path gas analyzer), sonic anemometer (CSAT3A sonic anemometer), data logger (CR6 datalogger), sample pump, three-valve module that enables automatic zero and CO2 span measurements (manual H2O span), and accommodations for a CDM-A116 analog input expansion module allowing for additional sensors.

The gas analyzer’s patented vortex intake design (United States Patent No. 9,217,692) and small sample cell volume (5.9 mL) provide a much lower flow rate than other closed-path systems while maintaining excellent frequency response (4.3 Hz cutoff frequency). Additionally, this design makes the system virtually maintenance free while still maintaining an ideal frequency response compared to traditional inline filters. Lower flow allows the CPEC310 to have one of the lowest total system power requirements (12 W) of any closed-path eddy covariance system. Campbell Scientific manufactures all components of the CPEC310, including the data logger and EasyFlux® DL software for computing and correcting fluxes, which gives our system the most reliable functionality.

Read More

Benefits and Features

- New conformal coating helps protect sonic transducers in corrosive environments

- Expandable, high-end system with CR6 datalogger processing power and EasyFlux® DL software to compute and fully correct up to 20 Hz data

- The 3-valve module makes the CPEC310 the only closed-path eddy covariance system on the market with the ability to perform automatic zero and CO2/H2O span

- Additional port options for energy balance and atmospheric sensors

- Ideal system for short or tall towers

- Simple design provides easy use while maintaining full functionality

EasyFlux® DL is a free CRBasic program for Campbell closed-path eddy-covariance systems that is available in the Downloads section. To learn more about EasyFlux® DL, visit the software product's web page.

Images

Detailed Description

The gas analyzer’s small sample cell volume (5.9 mL) minimizes the sample residence time (50 ms at the system’s nominal flow rate, 7 LPM). This gives excellent frequency response (5.8 Hz half-power bandwidth) with low total system power (12 W).

Eddy-Covariance Measurements

CO2 and H2O are measured with an EC155 Closed-Path Gas Analyzer. Three-dimensional wind speed and sonic air temperature are measured with a CSAT3A sonic anemometer head.

CPEC310 System Enclosure

The CPEC310 has two enclosures: a fiberglass enclosure that houses the CR6 datalogger, pump module, three-valve module, and optional CDM-A116, and the EC100 enclosure for data processing. The CPEC310 can also be equipped with a scrub module for automatic zeroing of the EC155.

CPEC310 Pump Module

The pump module, a standard component of the CPEC310 system, consists of a small dual-head diaphragm pump with a brushless dc motor mounted inside a fiberglass enclosure. An integral cable connects the pump module to the CPEC310 system enclosure, which provides power, temperature measurement and control, pressure measurement, and pumping speed measurement and control.

Specifications

| Operating Temperature Range | -30° to +50°C |

| Input Voltage Range | 10.5 to 16.0 Vdc |

| Power |

|

System Enclosure |

|

| Dimensions | 54 x 44.5 x 29.7 cm (21.3 x 17.5 x 11.7 in.) |

| Weight |

|

Pump Module |

|

| Inlet Connection | 3/8-in. Swagelok |

| Pressure Sensor Range | 15 to 115 kPa |

| Pumping Speed | 3 to 9 LPM (automatically controlled at the set point, typically 7 LPM) |

| Cable Length | 3.0 m (10 ft) |

| Dimensions | 35.6 x 29.2 x 13.5 cm (14.0 x 11.5 x 5.3 in.) |

| Weight | 5.4 kg (11.8 lb) |

Three-Valve Module |

|

| Inlets for Module | Zero, CO2, and H2O span |

| Outlets | Analyzer and H2O bypass |

| Connections | ¼-in. Swagelok |

| Dimensions | 14.0 x 12.7 x 14.0 cm (5.5 x 5.0 x 5.5 in.) |

| Weight | 1.5 kg (3.3 lb) |

Scrub Module |

|

| Power |

|

| Cylinder Volume | 480 cm3 each (29.29 in.3 each) |

| Molecular Sieve Size | 1.6 to 2.5 mm beads (0.063 to 0.098 in. beads) |

| Enclosure Dimensions | 39.4 x 34.3 x 20.3 cm (15.5 x 13.5 x 8.0 in.) |

| Weight | 9.6 kg (21.1 lb) |

Documents

Brochures

Manuals

Technical Papers

- The CPEC310 Advantage

- EC150, IRGASON, or EC155: Which CO2 and H2O Eddy-Covariance System Is Best for My Application?

- Quantifying Frequency Response of a Low-power Closed-path CO2 and H2O Eddy-covariance System

- Damping Temperature Fluctuations in the EC155 Intake Tube

- Molecular Sieve CO2 and H2O Scrubbing Solution

- Replacing the Vortex Intake in an Older EC155

- An eddy-covariance system with an innovative vortex intake for measuring carbon dioxide and water fluxes of ecosystems

Miscellaneous

- Performance Evaluation of an Innovative Sampling System for Closed Path Eddy Covariance Measurements

- Using Molecular Sieve to Zero Infrared Gas Analyzers for Eddy Covariance or Atmospheric Profile Measurements

- Field-Performance Verification of Carbon Dioxide, Water, and Nitrous Oxide Closed-Path Eddy Covariance Systems with Vortex Intakes Poster

Downloads

CR6 OS v.14.2.1 (8.73 MB) 07-04-2025

This download is for the CR6 datalogger. Execution of this download places the current CR6 Operating System file(.obj) and WiFi, RF45x and RF4xx operating systems (iobj) on your computer. It also updates the CRBasic Editor compiler and support files.

Why Update? New features and bug fixes. With this OS update it is recommended that you also update the Device Configuration Utility to the most recent version so that new datalogger features are available in the utility.

Note: Campbell Scientific always recommends updating operating systems on site if possible. When remote updates are required, it is recommended that you implement the necessary precautions to handle unexpected OS upload complications. All datalogger settings should be retained when updated remotely. If you choose to roll back to a previous operating system, the datalogger settings will be reset to default.

Watch the Video Tutorial: Sending an OS to a Local Datalogger.

EC100 OS v.8.02 (560 KB) 14-10-2019

EC100 Operating System.

Watch the Video Tutorial: Updating the EC100 Operating System.

ECMon v.1.6 (10.7 MB) 29-03-2016

EC100-Series Support Software.

Device Configuration Utility v.2.32.01 (47.7 MB) 15-04-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

EasyFlux DL for CR6CP v.1.08 (132 KB) 13-06-2024

CR6 datalogger program for Campbell closed-path eddy-covariance systems.

Frequently Asked Questions

Number of FAQs related to CPEC310: 6

Expand AllCollapse All

Case Studies

This case study discusses the integration of CPEC310 and AP200 systems to explore the theories......read more

Articles and Press Releases

Newsletter Articles

Privacy Policy Update

We've updated our privacy policy. Learn More