At a shorter height

Overview

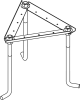

The UT6 is an aluminum, corrosion-resistant tower that provides a 6 ft (1.83 m) crossarm height. This general-purpose tower supports the attachment of sensors, mounts, solar panels, antennas, and environmental enclosures. The UT6 includes a lightning and grounding rod, grounding cables, grounding-cable clamps, hinged base, and UV-resistant cable ties. A J-bolt kit is used to secure the base to the concrete pad. This kit is ordered as an option, so it can be ordered separately and shipped before the rest of the tower.

The UT6 is used as a sturdy, long-term instrument mount for a variety of applications. It can be augmented with mounts (for example, CM204, CM220, CM225) that allow attachment of meteorological sensors such as wind sets, pyranometers, and temperature/relative humidity probes. Other meteorological sensors such as barometers, soil temperature and moisture probes, and rain gages can also be used with a UT6-based station.

Read More

Benefits and Features

- Sturdy, long-term instrument mount

- Shorter height for easier installation

- Base and grounding kit included

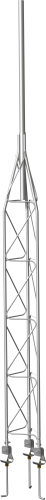

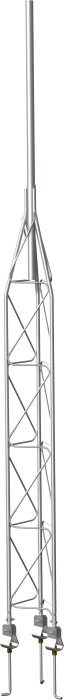

Images

Detailed Description

The tower consists of 2.5 cm (1 in.) OD corrosion-resistant aluminum tubing. In cross-section, it is 25.7 cm (10.1 in.) on a side (center of tubing to center of tubing). It includes an adjustable mast, a hinged base, lightning rod, grounding rod, and cable tie kit.

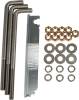

The J-bolt kit is required to assemble the tower to its concrete pad.

- The J-bolt kit can be ordered as the -J option, and the kit is delivered with the rest of the tower.

- If the -NJ option is ordered, without the J-bolt kit, and the kit is ordered separately, the user can have delivery on the J-bolt kit prior to the rest of the tower, making the parts available when the concrete pad is poured.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Mounting Equipment

| Product | Compatible | Note |

|---|---|---|

| CM204 |

Additional Compatibility Information

Enclosure Brackets

The “-TM” mount option for our environmental enclosures is used to attach our enclosures to a UT6 tower. An enclosure ordered with the “-TM” option will be shipped with a three-piece bracket mounted to the top of the enclosure and an identical three-piece bracket mounted to the bottom of the enclosure. This mounting bracket option uses the same three-piece brackets as the "-MM" option, except the pieces are rearranged so that the flanges are on the side of the bracket instead of in the middle. The distance between the centers of each flange needs to be 10.25 in.

Specifications

| Material | Hardened drawn 6063-T832 aluminum |

| Required Concrete Pad Dimensions |

61 x 61 x 61 cm (24 x 24 x 24 in.) Concrete pad requirements assume heavy soil; light, shifting, or sandy soils require a larger concrete pad. |

| Leg Spacing | 26 cm (10.25 in.) between legs, center to center |

| Pipe Outer Diameter |

|

| Crossarm Height (attached to mast) |

|

| Height | 1.83 m (6 ft) |

| Weight | 10.43 kg (23 lb) |

Maximum Wind Load Recommendation |

|

| -NOTE- |

Wind load endurance is affected by quality of anchoring and installation; guy wire tension; soil type; guy angle; and number, type, and location of instruments fastened to the tower. Wind load recommendation assumes proper installation, proper anchoring, adequate soil, and total instrument projected area of less than 0.19 m2 (2 ft2) at the height of the tower. |

| Wind Load Recommendation | 177 km/h (110 mph) for gusts |

Documents

Privacy Policy Update

We've updated our privacy policy. Learn More